October 19, 2022, Vancouver, British Columbia – Surge Copper Corp. (TSXV: SURG) (OTCQX: SRGXF) (Frankfurt: G6D2) (“Surge” or the “Company”) is pleased to announce results from its recently completed metallurgical testwork program focused on the Seel deposit, located on the Ootsa Property in central British Columbia. This testwork program was designed to advance bulk copper-molybdenum concentrate flotation parameters, confirm molybdenum recovery performance into a separate molybdenum concentrate at marketable grades, and investigate further opportunities to increase precious metal recoveries from tailings streams within the flowsheet. Surge engaged ALS Metallurgy Kamloops to complete the testwork program which ran from February 2022 to October 2022.

Highlights

- Large-scale flotation testwork program utilizing a set of 4 composites made up of 2,000 kilograms of sample material representative of different rock types, grades, and volumes within the deposit

- Excellent overall molybdenum recoveries from bulk circuit feed to molybdenum concentrates of 75 to 82 percent at molybdenum concentrate grades of 47 to 52 percent, including high separation recoveries relative to bulk concentrate feed of between 90 to 97 percent

- Confirmation of robust copper and precious metal recoveries in locked cycle tests across all composites using standardized parameters resulting in copper concentrates grading between 27 to 29 percent copper, with copper recoveries ranging from 83 to 90 percent, gold recoveries ranging from 47 to 60 percent, and silver recoveries ranging 41 to 68 percent

- Confirmation of potential for additional leach recoveries of gold from tailings streams

Leif Nilsson, Chief Executive Officer, commented: “Overall, this testwork program was quite successful in that it greatly improved our understanding around some key variables, and generally advanced our knowledge on metallurgical performance for this deposit, further preparing us for future advanced economic or engineering studies. A standardized set of parameters was able to produce the desired metal recoveries and give the Surge team great confidence that the varying lithologies and grade ranges will perform in an operational scenario.”

The Seel deposit forms the largest overall component of the recently updated mineral resources at Ootsa (see press release dated June 21, 2022). This testwork program utilized a set of 4 composites comprised of approximately 2,000 kilograms of sample material derived from 9 separate core holes drilled from the West Seel zone during the 2020-2021 exploration program. All of the sample material falls within the current resource estimate, with depths ranging from near-surface at 32 metres downhole depth, to deeper portions of the deposit at 528 metres downhole depth. The program builds on prior testwork programs completed between 2012 and 2014 that were focused on the East Seel zone, the West Seel zone, and the Ox deposit at Ootsa. These prior programs showed greater than 90 percent recovery of copper to a marketable concentrate in both cleaner flotation and locked-cycle flotation tests and showed positive results from 3 unoptimized copper-molybdenum separation tests. Collectively, these testwork programs provide confidence in the ability to use standard comminution and flotation flowsheets to recover copper, molybdenum, gold, and silver into marketable concentrates at robust recovery rates from the distinct mineralized zones that comprise the mineral resources at Ootsa.

Metallurgical Testwork Program Details

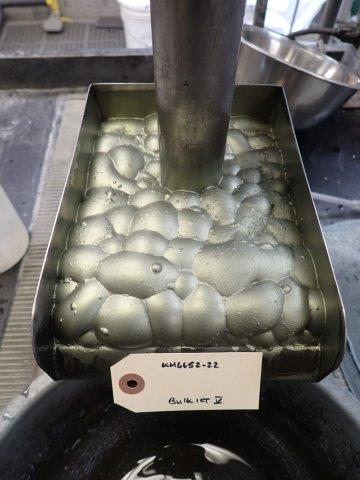

In the 2022 program, samples were sent to ALS Metallurgy in Kamloops and subjected to crushing, grinding, and flotation for recovery of copper, molybdenum, gold, and silver. The first phase of the program consisted of 8 rougher flotation tests, 12 cleaner flotation tests, and 4 locked-cycle flotation tests focused on producing a bulk copper-molybdenum concentrate. The best result from this phase of the program produced approximately 90% copper recovery, with the 4 locked-cycle tests across the 4 composites averaging 87% recovery to a concentrate with an average grade of 27% copper. The finalized test parameters used a primary grind size of 125 microns with a rougher concentrate regrind to 20 microns, and 3418A as the collector. Table 1 provides a simplified summary of the test results from the bulk circuit locked-cycle tests, and Figure 1 shows an image of a bulk concentrate during a cleaner test, demonstrating the froth quality.

|

Table 1. Simplified Test Results from the Bulk Circuit Locked-Cycle Tests |

|||||||||

|

|

|

||||||||

|

|

Concentrate Grade |

|

Recovery |

||||||

|

Composite |

Cu |

Mo |

Au |

Ag |

|

Cu |

Mo |

Au |

Ag |

|

(#) |

(%) |

(%) |

(g/t) |

(g/t) |

|

(%) |

(%) |

(%) |

(%) |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

27.3 |

2.3 |

11.9 |

241 |

|

88.4 |

74.0 |

54.6 |

44.5 |

|

2 |

26.7 |

2.6 |

10.3 |

278 |

|

82.9 |

71.4 |

46.7 |

68.4 |

|

3 |

28.5 |

3.6 |

14.6 |

267 |

|

89.6 |

79.4 |

59.8 |

62.9 |

|

4 |

27.3 |

1.7 |

11.0 |

264 |

|

87.7 |

75.0 |

52.4 |

40.7 |

Figure 1. Flotation froth quality.

Following the confirmation of test parameters for bulk flotation, the composites were then processed using the developed test parameters to create a large volume of bulk concentrate for copper-molybdenum separation testing. In this second phase of the program, 8 copper-molybdenum separation cleaner tests were run using a variety of test parameters with the final 4 separation cleaner tests run under final conditions across each of the composites. Results for separation testing found high recoveries to molybdenum concentrates with molybdenum grades approaching or exceeding 50% and considered saleable. The best result demonstrated a molybdenum recovery relative to the bulk concentrate feed of 97% to a concentrate grading 47% molybdenum, with an average recovery relative to bulk concentrate feed across all 4 composites of 93% into concentrates with an average molybdenum grade of 50%. Table 2 provides a simplified summary of the test results showing the characteristics of the separate molybdenum and copper concentrates. Over the course of the program, the various tests produced a total of 5.6 kilograms of copper concentrate and 284 grams of molybdenum concentrate.

|

Table 2. Simplified Test Results from Bulk Concentrate Generation and Molybdenum Separation Tests |

|||||||||

|

|

|

||||||||

|

|

Concentrate Grade |

Recovery* |

|||||||

|

Composite |

Cu |

Mo |

Au |

Ag |

|

Cu |

Mo |

Au |

Ag |

|

(#) |

(%) |

(%) |

(g/t) |

(g/t) |

|

(%) |

(%) |

(%) |

(%) |

|

Molybdenum Concentrates |

|

|

|

|

|

|

|

|

|

|

1 |

1.0 |

46.8 |

3.9 |

30 |

|

0.1 |

74.9 |

0.8 |

0.3 |

|

2 |

0.4 |

50.4 |

3.1 |

32 |

|

0.1 |

81.5 |

0.9 |

0.5 |

|

3 |

0.8 |

51.2 |

5.1 |

36 |

|

0.2 |

82.2 |

1.0 |

0.6 |

|

4 |

0.4 |

52.4 |

1.8 |

52 |

|

0.0 |

76.4 |

0.3 |

0.3 |

|

Copper Concentrates (combined rougher and cleaner tailings from molybdenum separation) |

|

|

|||||||

|

1 |

26.3 |

0.1 |

11.8 |

221 |

|

89.3 |

2.6 |

55.8 |

48.3 |

|

2 |

26.1 |

0.1 |

9.6 |

257 |

|

82.0 |

4.0 |

50.5 |

67.3 |

|

3 |

24.4 |

0.3 |

15.6 |

193 |

|

89.1 |

9.1 |

55.8 |

58.5 |

|

4 |

23.2 |

0.1 |

9.6 |

230 |

|

84.5 |

7.4 |

50.1 |

41.6 |

|

*All recoveries are relative to composite feed grade and represent overall metallurgical recoveries. |

|

|

|

||||||

The test program also included various tests to indicate whether additional gold and silver recoveries could be made. Additional testing was completed on several samples of a flotation pyrite rougher concentrate mixed with a first cleaner tails of the copper flotation process of the respective composites. A standardized set of test parameters that included a re-grind stage, pre-aeration and oxygen sparging was then run on leach composites made from each main composite. Final leach results showed promise with gold recoveries relative to the leach composite feed of up to 87 percent from the leach composite constructed from test Composite 3. Results showed average gold recoveries relative to leach composite feed of 75 percent from all leach composites. Additional studies will be required to evaluate the economic recovery of adding such a system to the overall flow sheet that takes into account reagent and operating costs being offset by additional recoveries.

Upcoming Catalysts

The Company anticipates updating the market on results from the following activities:

- Drill results from 2022 regional exploration program

- Berg project updates

Quality Control

This metallurgical testwork has been undertaken at ALS Metallurgy Kamloops which conforms to ISO 9001:2015. The laboratory also conducts internal QC checks to ensure data is reported accurately. The analytical lab voluntarily partakes in the Proficiency Testing Program for Mineral Analysis laboratories (PTP-MAL). Samples of half core were delivered and, following some comminution testing, were stage-crushed to -6 mesh (3.35 mm), homogenized into composites, and rotary split into test charges. Head samples were split from each of the sub-samples for assay. Each of the master composites has been analyzed by standard analytical techniques. Mineralogical analysis was conducted by QEMSCAN.

Qualified Persons

Dr. Shane Ebert P.Geo., is the Qualified Person for the Ootsa and Berg projects as defined by National Instrument 43-101 and has approved the technical disclosure contained in this news release.

Mark Wheeler, P.Eng., VP of Projects at the Company as well as a Qualified Person as defined by National Instrument 43-101, has supervised the preparation of the technical information in this news release.

About Surge Copper Corp.

The Company owns a 100% interest in the Ootsa Property, an advanced stage exploration project containing the East Seel, West Seel and Ox porphyry deposits located adjacent to the open pit Huckleberry Copper Mine, owned by Imperial Metals. The Ootsa Property contains pit constrained NI 43-101 compliant resources of copper, gold, molybdenum, and silver in the Measured and Indicated categories.

The Company is also earning into a 70% interest in the Berg Property from Centerra Gold. Berg is a large, advanced stage exploration project located 28 km northwest of the Ootsa deposits. Berg contains pit constrained 43-101 compliant resources of copper, molybdenum, and silver in the Measured and Indicated categories. Combined, the adjacent Ootsa and Berg properties give Surge a dominant land position in the Ootsa-Huckleberry-Berg district and control over four advanced porphyry deposits.

On Behalf of the Board of Directors

“Leif Nilsson”

Chief Executive Officer

For further information, please contact:

Riley Trimble, Corporate Communications & Development

Telephone: +1 604 416 2978

Email: info@surgecopper.com

Twitter: @SurgeCopper

LinkedIn: Surge Copper Corp

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This News Release contains forward-looking statements, which relate to future events. In some cases, you can identify forward-looking statements by terminology such as "will", "may", "should", "expects", "plans", or "anticipates" or the negative of these terms or other comparable terminology. All statements included herein, other than statements of historical fact, are forward looking statements, including but not limited to the Company’s plans regarding the Berg Property and the Ootsa Property. These statements are only predictions and involve known and unknown risks, uncertainties and other factors that may cause the Company’s actual results, level of activity, performance, or achievements to be materially different from any future results, levels of activity, performance, or achievements expressed or implied by these forward-looking-statements. Such uncertainties and risks may include, among others, actual results of the Company's exploration activities being different than those expected by management, delays in obtaining or failure to obtain required government or other regulatory approvals, the ability to obtain adequate financing to conduct its planned exploration programs, inability to procure labour, equipment and supplies in sufficient quantities and on a timely basis, equipment breakdown, impacts of the current coronavirus pandemic, and bad weather. While these forward-looking statements, and any assumptions upon which they are based, are made in good faith, and reflect the Company's current judgment regarding the direction of its business, actual results will almost always vary, sometimes materially, from any estimates, predictions, projections, assumptions, or other future performance suggestions herein. Except as required by applicable law, the Company does not intend to update any forward-looking statements to conform these statements to actual results.